The Ultimate Guide to Push Buttons

This helpful guide has been designed to learn how pushbutton switches work, their uses and the different types available, so you can find the best switch for your application

Pushbutton switches are an important component of electrical and electronic circuits because they help control the flow of current sent to devices. Simple but incredibly effective, this type of switch ensures safety and efficiency of systems while making them easier to use.

What is a push button?

A push button controls an action or process in a machine. Also called push-button switches, these small, but fundamental, components are found almost everywhere! In fact, they are used to interface the order given by humans to a machine. They are therefore commonly used at home, in transport and in the workplace.

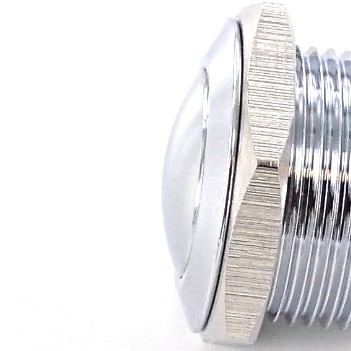

They are designed to be easily identifiable, and the buttons will generally be made from durable and resistant materials such as plastic or metal ensuring them a very long lifespan. The shape of the button can be either flat, protruding or convex, or customized according to ergonomic specifications. There are a wide variety of models available, driven by either momentary action or sustained action.

How does a push button work?

Most push buttons work the same way. Pressure is exerted by the operator on the button actuator, which causes depression of the internal spring acting on the contact located in the switch. This process will close or open the contact and therefore the electrical circuit to which it is connected. You can choose between pushbuttons with normally open (NO), or normally closed (NC or NC) contacts, which change state upon actuation.

What is the difference between NO and NC contacts?

The NC contact (forNormally Closed) designates a “Normally Closed” (NC) contact, that is to say that at rest the circuit is closed, contact between the two poles is established and the current passes through the circuit. When the push button is activated, the contact opens and current no longer flows in the circuit.

A NO contact is a “Normally Open” contact (orNormally Open), that is to say that at rest the circuit is open, contact between the two poles is not established. When the push button is pressed, the contact closes; current passes through the circuit.

There are also NONC contacts (for Normaly Open and Normaly Closed) which can be both Normally Open and Normally Closed (as defined by the acronym NONF)

This type of contact has many advantages:

- Functional: a classic switch has an input and an output. It can be NO (Normally Open) or NC (Normally Closed). A switch with a NONF function has one input and 2 outputs, with therefore 2 possible actions. A default action when idle and a second action when activated.

- Safe / redundancy function: A NONF switch also offers a redundancy function. It allows you to check the proper functioning of the system and therefore of the device on which it is mounted.

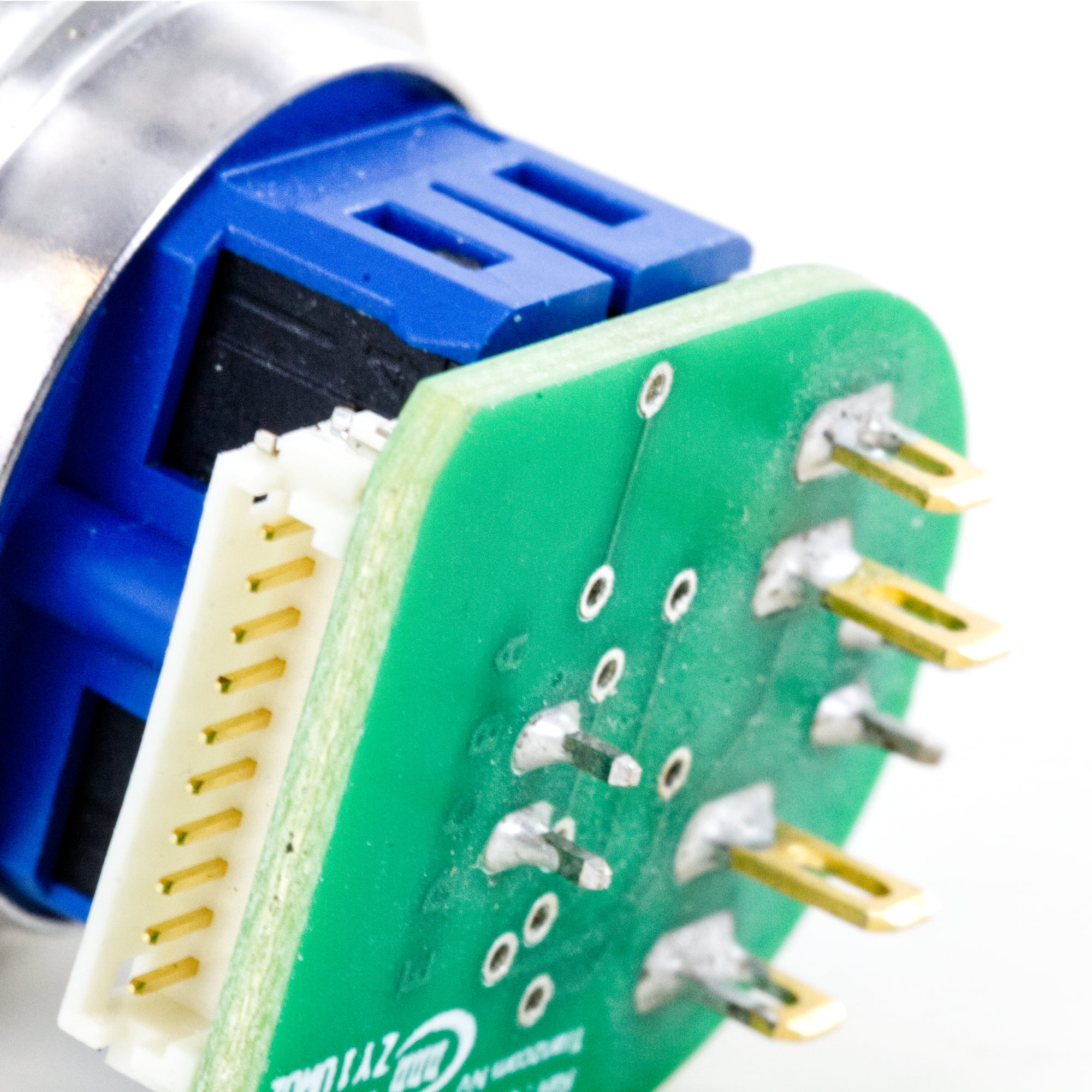

The photo below shows a push button equipped with a NONC contact.

What is the difference between momentary and maintained push buttons?

Continuous pressure must be held on the button of a momentary switch to cause action. Once the button is released, the switch will return to its resting state. This is useful for temporary activations, such as intercom systems for example.

Maintained push buttons (bistable oralternate) will remain in the set contact state until pressure is reapplied, which will then return them to their original state. They are used for applications such as start/stop functions for machines, lighting systems or alarms.

Push Button Switch Voltage Ratings

Not all push buttons accept the same type of electrical current. Two essential concepts should be remembered:

- nominal current: Maximum current that can pass through the already closed contacts of a switch.

- Breaking capacity: The ability of the button to switch (switch) an electric charge. The load can be capacitive, resistive or inductive. Opposes rated current.

Don't assume that a push button will work as long as it can handle the maximum current in your circuit. It must be designed for alternating current and/or direct current circuits. The speed at which the switch can open the circuit depends on whether you are dealing with AC or DC connections. Also think about what type of load your circuit will be dealing with – whether it's a motor (inductive load) or a simple resistor. This will affect whether the switch is suitable or not.

See ourglossaryfor more details on the electrical variables to consider in your choice.

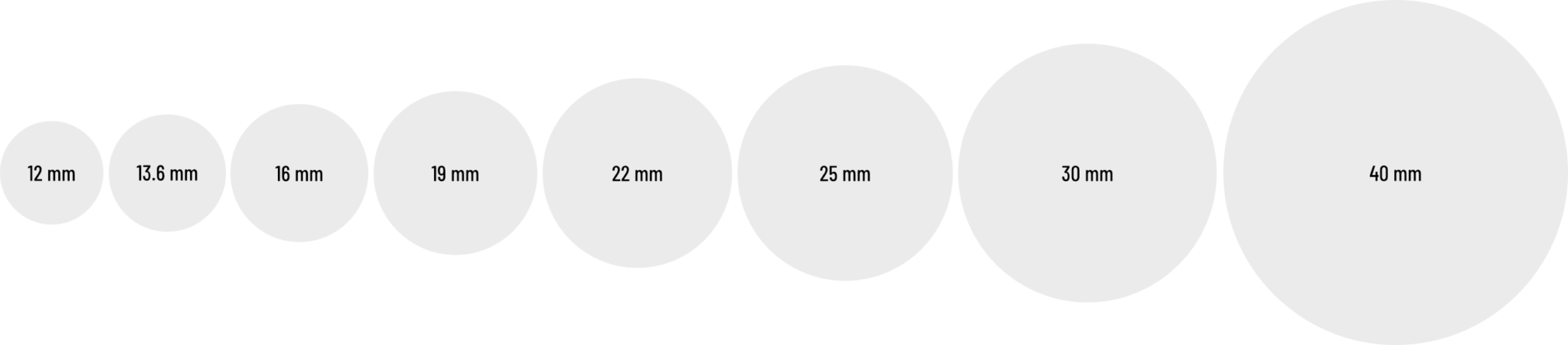

About drilling diameter

A push button is installed, in the majority of cases, in a hole on a panel. The diameter of this hole will directly depend on your choice of design, the size of the machine, the importance given to the function provided by the button, etc.

The different commonly used and standardized diameters are shown below.

Other smaller buttons, intended for electronic applications, and not necessarily installed on a panel exist; they are generally soldered directly onto a printed circuit board.

The benefit of an illuminated push button?

Illuminated pushbuttons provide a much higher level of visibility for the switch location. The lighting also makes it possible to indicate the state in which the contact is. They are equipped with integrated LEDs and are easily visible in low light environments, such as on industrial machines, embedded equipment or in contact with the general public.

Several types of lighting exist: illuminated central disc, illuminated crown or even illuminated logo, they can also include a fully illuminated key. The integrated LEDs can be single-color, bi-color or RGB (red/green/blue). Certain ranges of buttons offered by Kynoppe are equipped with LEDs even allowing millions of colors to be simulated (like the rangeSIRIUS).

Kynoppe has recently offered its customers a U.DESIGN service of personalized illuminated logos: inexpensive, easy to implement, it helps to reinforce the visual impact of your application: The illuminated logos can be personalized to match your image brand and style of your company.contact usfor more information !

About Connectivity

The push buttons are connected to the electrical circuit by their “output”, part of the switch, external to the body, which is used to connect it to it.

Several types of outputs exist: solder lugs, faston or mini-faston lugs, screw terminals, spring terminals, completely waterproof wire or cable output, quick connector, etc.

Kynoppe offers its customers a tailor-made wiring service for its buttons.contact usfor more information !

- Pods

- Screw terminals

- Wires/Cable

- Connector

- Spring terminals

solder lugs

The most common and popular type of output. Wires are soldered directly to the lugs.

solder lugs

Sometimes specific footprints also allow them to be soldered onto a printed circuit.

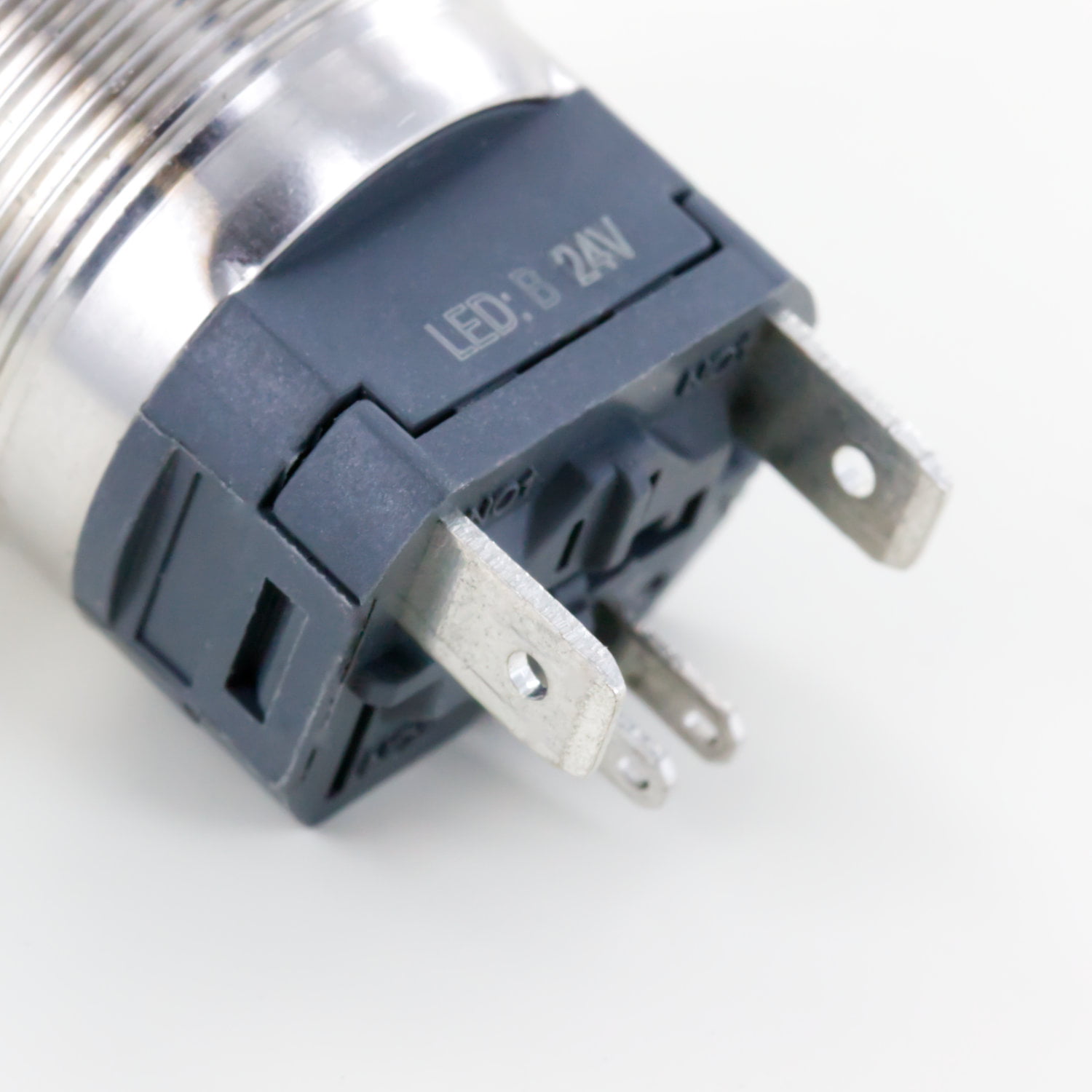

2.8 lugs

Also called mini-faston lugs. These terminals are very interesting because they not only allow the use of 2.8 female crimp terminals but also the soldering of wires. In certain cases, also compatible with quick connector.

flat terminals 6.3 or 5

These terminals are very interesting because they not only allow the use of female crimp terminals but also the soldering of wires. In certain cases, also compatible with quick connector.

Screw terminals

The screw terminals are easy to use and allow the button to be installed on site without the need for specific tools: no soldering or crimp terminals required. For certain applications where vibrations are omnipresent (transport for example), the use screw terminals should be avoided, if we want to avoid retightening campaigns...

screw terminals

Example of screw terminals on a 22mm diameter industrial button equipped with a NO contact.

Wire output

Totally waterproof wire outlet. The wires are soldered on terminals and the back of the button is entirely protected by an epoxy resin, which ensures IP67/68 waterproofing also on the button outlet. This type of outlet is particularly recommended in very humid environments (swimming pools, spas). , transport, car wash etc...)

cable outlet

Totally waterproof IP68 cable outlet

Quick connector

An option offered on certain ranges of our anti-vandal buttons (SOAV2, SOAV3, SOAV4, SOAV5, SIRIUS, ORION), the quick connector substantially facilitates the installation of the button in its working environment. It also makes maintenance operations easier. Available in a hardwired kit, it is also offered pre-wired equipped with 15cm wires.

Custom quick connector

Example of customization: Fully waterproof output with waterproof circular connector.

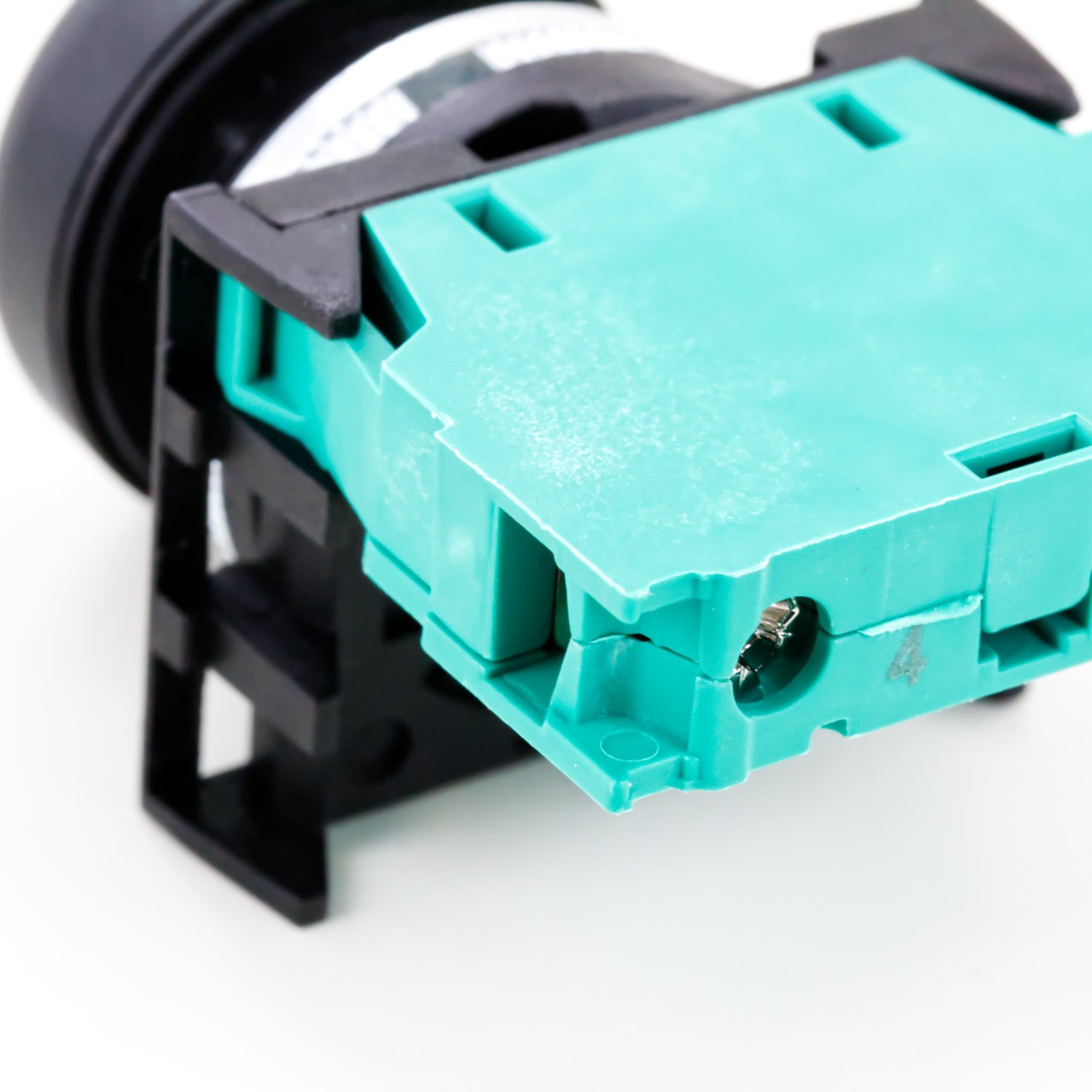

Spring terminals

Type of terminals increasingly used on "industrial" type buttons dia.22mm for machine control. This output speeds up wiring operations thanks to its spring-equipped terminals.

What are the different types of keys

The push buttons are equipped with keys of different shapes, with round and rounded keys being among the most common versions. You will also find shapes such as mushroom head, protruding, with collar, selector type etc…

Are the push buttons waterproof?

If your application requires a good level of waterproofing, you will need to look for a button with a high IP rating, such as IP65, IP66, IP67, IP68, or IP69K. This index, standardized and standardized, indicates the level of protection of a device against humidity and particles. A button with an IP65 rating will be protected against low pressure water jets, while a button rated IP69K will be protected against high pressure and high temperature jets, washdowns and steam cleaning procedures.

Our technical glossaryexplains the different IP classes

Our sensitive push buttons (piezo and capacitive) are IP68/IP69K.

The majority of our electromechanical push buttons have an IP67 rating. The sealing can be improved by combining the button with a silicone sealing cap (high pressure washing becomes possible here). Some buttons are designed to automatically incorporate a silicone button.

What are the main types of push buttons?

There are many different types of push buttons, each with unique benefits. The version you need will depend on factors specific to your application such as the intended task, type of button, number and type of contacts, IP rating etc.