Il est essentiel pour toute application IHM de choisir le voyant ayant une intensité lumineuse qui soit compatible avec son environnement de travail : en effet, l’état de l’équipement doit être lisible / visible, et ce, en toute situation.

Mais l’intensité lumineuse n’est pas la seule caractéristique variable à prendre en considération dans la sélection du voyant « parfait ».

Petit guide sous forme de FAQ’s :

- Utilisation intérieure ou extérieure ? La lumière naturelle est une source de lumière très intense, même par temps nuageux. Ainsi l’intensité du voyant doit être beaucoup plus élevée pour que celui-ci soit visible en plein jour.

- Distance : l’intensité nécessaire pour voir un voyant lumineux proche ou lointain est très différente. L’intensité lumineuse doit donc augmenter avec la distance.

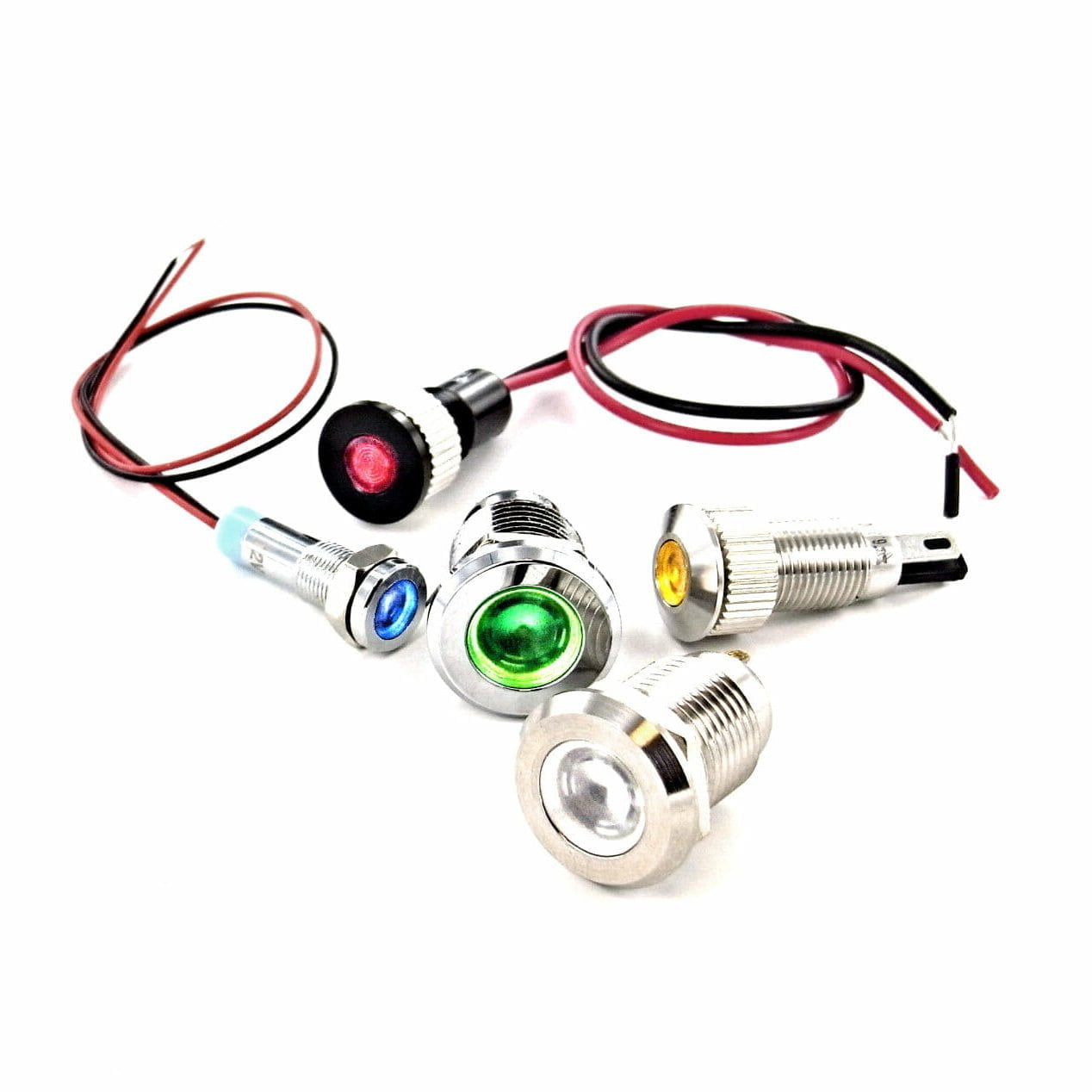

- Les couleurs : une, deux, trois couleurs ou champ RVB ? il est important de garder à l’esprit que la lumière de couleur bleue ou blanche se diffuse plus aisément. En revanche, la lumière rouge ou verte est plus nette.

- La taille du voyant et de sa lentille : cela semble évident, mais il est important de rappeler que la taille de la lentille et sa forme définiront la façon dont la lumière sera diffusée

En tout état de cause, l’intensité lumineuse du voyant est une variable essentielle à prendre en considération dans le choix de l’indicateur car elle doit permettre de discerner avec précision l’état de fonctionnement de l’application mais elle peut aussi renforcer la confiance des utilisateurs dans les applications ou la sécurité est primordiale.

Pour une visibilité assurée en toutes conditions – même en plein soleil – Kynoppe propose en option l’intégration de LEDs à haute luminosité.

Pour connaître la valeur de l’intensité lumineuse de nos voyants, se référer aux fiches techniques.

Nos voyants sont proposés en alimentation 3V, 6V, 12V, 24V, 110V ou 220V.

Il est néanmoins important de respecter les charges recommandées car la LED est un composant électronique particulièrement sensible aux variations de tension.

Nous recommandons donc l’utilisation systématique d’une résistance de protection pour ajuster au mieux la tension d’alimentation et éviter que des pics n’endommagent la LED.

Les matériaux utilisés et le type de LED déterminent généralement les plages de température de fonctionnement du voyant.

La plage de fonctionnement typique de nos voyants est -40°C à +85°C mais il est important de préciser que celle-ci peut-être affectée par la conception et l’environnement de travail.

- sortie à fils : le voyant est connecté à la source d’alimentation par des fils qui doivent être suffisamment longs pour passer du panneau au circuit imprimé. La taille standard des fils variera selon le produit et peut être personnalisée pour s’adapter à la conception de l’appareil. La sortie fils assure en outre une étanchéïté électrique supérieure. Reportez-vous à la fiche technique ou sur Kynoppe.com pour obtenir des informations sur le fil conducteur.

- cosses à souder : des languettes métalliques sont utilisées pour connecter l’indicateur à la source d’alimentation soit en y soudant des fils de cablage soit en implantation directe sur circuit imprimé. Dans certains cas, les cosses peuvent aussi accepter des cosses femelles quickconnect. Reportez-vous à la fiche technique ou sur Kynoppe.com pour obtenir les informations techniques requises.

- bornes à vis : des bornes avec vis de serrage sont utilisée pour connecter le voyant au circuit via des fils de câblage.

|  |  |

|

| sortie à fils | sortie à fils | cosses à souder | bornes à vis |

La lentille est un « cou », ou « manche » qui enveloppe la LED. Elle peut être utilisé pour protéger l’indicateur de l’humidité et de la poussière, ou pour améliorer l’esthétique de la conception.

Sa teinte et sa forme impactera directement le rendu visuel du voyant.

- Forme Concave : Utilisé lorsque la confidentialité de l’état de l’appareil est requise ou visible uniquement par l’opérateur. Angle de vision inférieur à 30°

- Forme rasante : Idéal lorsque la visualisation de l’état doit être faite en lecture directe, face au voyant avec un angle de vision compris entre 30 et 45°

- Forme dépassante et bulbe : Idéal pour les appplications où l’état de l’appareil doit être aisément identifiable, même en vision périphérique. Angle de vision supérieur à 100°

|  |  |  |

| forme concave | forme rasante | forme dépassante | forme bulbe |

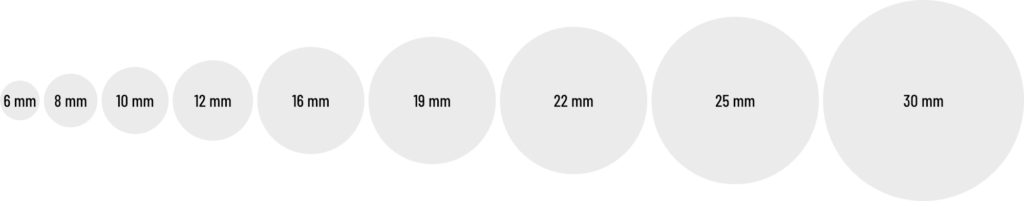

Chaque design est unique. Ainsi, la gamme Kynoppe offre un large éventail de tailles de trous de montage pour aider ses clients à concevoir une interface utilisateur attrayante et efficace.

Nos diamètres de perçage vont de 6 mm à 30 mm, avec la possibilité de créer des tailles personnalisées pour répondre aux spécifications de conception si la quantité minimale de commande appropriée est respectée.

De même, nous proposons un méplat optionnel lorsque l’anti-rotation est requise (MOQ 200 pcs).

Veuillez vous référer à la fiche technique du produit.

NotaIP65 – étanche à la poussière et protégé contre l’eau projetée par une buse.IP67 – étanche à la poussière et protégée contre les jets d’eau et les vagues complets et forts.

Typiquement, la durée de vie d’une lampe pour chaque type de technologie d’éclairage est la suivante:

- LED: 40 000 à 100 000 heures

- Néon: 25 000 heures

- Incandescence: 1 000 heures à 1 500 heures

Variables qui peuvent avoir un impact négatif sur la durée de vie des voyants :

- Tension de fonctionnement

- Température de fonctionnement

- Exposition à des pics de tension

- Chocs mécaniques et vibrations

- Fréquence d’émission et d’arrêt

Bien entendu le type de lampe utilisé dans l’indicateur de montage sur panneau aura un impact sur la durée de vie globale du voyant.

Étant donné que les LEDs durent en moyenne 133 fois plus longtemps que les ampoules à incandescence, elles réduisent considérablement les coûts de maintenance et d’exploitation sur la durée de vie de l’appareil. C’est pourquoi Kynoppe ne propose que des voyants équipés de LEDs.

- Faisceau de câble personnalisé:

- Longueur, section et terminaison du fil

- Luminosité des LED

- Angle de vision LED

- Indicateurs bicolores et tricolores

- Couleurs des lentilles

- Finitions du corps : Inox, plastique, ou aluminium anodisé

- Styles de lunette – encastrées, affleurantes ou proéminentes

Le MOQ pour un voyant personnalisé dépendra du volume de commande et de la personnalisation requise pour la conception. Typiquement, un voyant personnalisé nécessiterait une commande d’au moins 3 000 unités. Cependant, il y a des cas où le MOQ peut être beaucoup moins important. N’hesitez pas à nous contacter pour discuter de vos besoins spécifiques en matière de conception.

Nos experts orientés « solutions » peuvent travailler avec vous pour concevoir et fabriquer exactement ce que vous aviez en tête : sales@kynoppe.com

Selon les matériaux, l’application, la taille, les caractéristiques et la personnalisation, la fourchette de coûts typique est de 1 à 6 € par unité.

Cependant, les voyants avec une personnalisation et des fonctionnalités étendues peuvent coûter plus de 20€ par unité.

Notre équipe est disponible pour trouver avec vous la solution présentant le rapport fonctionnalité/coût le plus optimal.

Voyants LED étanches à cosses

Série SOIN_J

Une gamme étendue d'indicateurs à LED étanches du diamètre 8mm à 30mm. Disponible en corps Inox, Aluminium ou Laiton Nickelé.

Découvrir la gammeVoyants LED étanches à fils

Série SOIN_F

Une gamme étendue d'indicateurs à LED étanches du diamètre 6mm à 16mm. Disponible en corps Inox, Aluminium ou Laiton Nickelé.

Découvrir la gamme

-

Voyant Led étanche Bulbe dia.22mm

Note 0 sur 5à partir de 8,80 € HT -

Voyant Led étanche rasant dia.12mm

Note 0 sur 5à partir de 4,43 € HT -

Voyant LED étanche dia.6mm

Note 0 sur 5à partir de 2,72 € HT -

Voyant LED étanche dia.22mm

Note 0 sur 5à partir de 5,22 € HT -

Voyant LED étanche dia.22mm

Note 0 sur 5 -

Voyant LED étanche dia.14mm

Note 0 sur 5 -

Voyant LED étanche dia.10mm

Note 0 sur 5